We are familiar with the conditions, technical specifications, and industry standards of various semiconductor fabs, high-end precision laboratories, LCD panel factories, and optical instrument manufacturing factories. Guided by customer needs, we leverage innovative products and extensive successful experience to provide customers with high-quality equipment customized solutions.

We have developed a professional 'international engineering organizational structure' designed to effectively support the growth and innovation of both domestic and global businesses. By leveraging globally distributed engineering teams, clear division of responsibilities, and collaborative mechanisms, seamless collaboration across time zones and regions can be achieved. This architecture enables us to respond promptly to local market demands, share global technological resources, and consistently provide high-quality, international products and services, thereby driving the company's success in the global market.

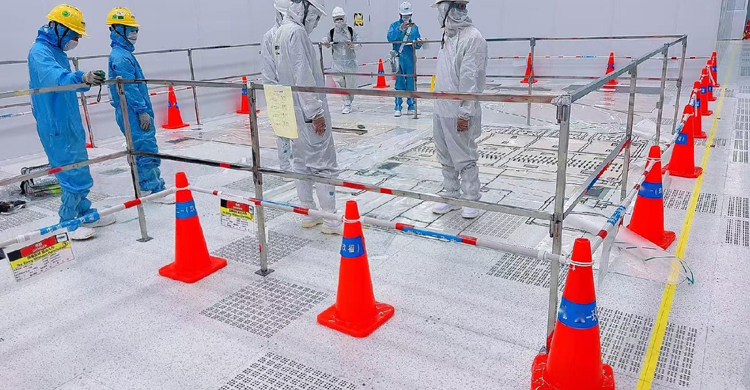

On-site management and construction personnel have extensive industry experience, hold all necessary qualifications, and are fully certified to work. Both domestic and international projects implement a standard configuration of "one-position-one-role" assignment, while for larger projects, a flexible "one-position-multi-role" deployment is employed. By combining a scientific control system, a technical approach involving pre-construction of key processes and pre-verification of critical procedures is adopted to achieve visualized on-site operations.

Based on the safety management laws, regulations, and industry experience from both domestic and international engineering projects in China, we have improved and implemented a scientific safety management system. Through pre-entry personnel screening and assessment, a training system, daily toolbox meetings (TBM), pre-control mechanism for safety risk sources, safety management element mechanism, fixed-point supervision mechanism, scientific and efficient SOP mechanism and periodic review mechanism, we provide clients with a scientific safety management ecological environment that achieves zero accidents and an extremely low violation rate.

We have implemented a quality management system centered on data and processes. Through detailed process control, scientific measurement analysis, and a closed-loop mechanism for continuous improvement, we ensure that every stage from design to delivery is precise, controllable, and continuously optimized, providing a solid guarantee for the excellent quality of our products and services.

Make informed decisions using real-time data, adapt to changes through agile methods, and make accurate predictions with scientific models. This system empowers project teams to have complete control over progress, swiftly adapt to changes, and guarantee efficient delivery, serving as a crucial driver for achieving project goals. We implement dedicated control for every single equipment unit throughout the following stages to ensure a smooth Move-In ahead of schedule: from obtaining the original drawings to the completion of product drawing approval in the design process; from production of products at the factory to the logistics and transportation process; as well as on-site installation process, on-site testing and acceptance process., Each stage is managed and adjusted according to the planned nodes.